Mastering Agile Manufacturing and Late Stage Customization with Strategic Partnerships

In order for brand companies to react and adapt to rapid changing consumer demand and retail requirements, remaining agile and nimble is essential. How this rapid change manifests in the supply chain, however, can be difficult to manage. Until recent years, supply chains within large brand companies were designed to produce the same product over and over again with massive volume quantities and at maximum efficiency. Now, when the retailer – or consumer – demands customization, this can be difficult. Compounding this complexity is the connection between the consumer and social media, which has created an environment where trends emerge and fade quickly, customization is expected, and smaller, nimble brands are challenging the status quo of their monolithic counterparts. The impact is felt by nearly every brand company. As a result, brand companies are re-evaluating their supply chain to allow for mass customization and innovation – they’re finding, however, that this endeavor is not possible without the help of strategic supplier partners to help them succeed and remain relevant. This article discusses how brand companies can leverage their supplier network to answer the needs of the consumer, innovate rapidly, and achieve their speed to market goals.

In order for brand companies to react and adapt to rapid changing consumer demand and retail requirements, remaining agile and nimble is essential. How this rapid change manifests in the supply chain, however, can be difficult to manage. Until recent years, supply chains within large brand companies were designed to produce the same product over and over again with massive volume quantities and at maximum efficiency. Now, when the retailer – or consumer – demands customization, this can be difficult. Compounding this complexity is the connection between the consumer and social media, which has created an environment where trends emerge and fade quickly, customization is expected, and smaller, nimble brands are challenging the status quo of their monolithic counterparts. The impact is felt by nearly every brand company. As a result, brand companies are re-evaluating their supply chain to allow for mass customization and innovation – they’re finding, however, that this endeavor is not possible without the help of strategic supplier partners to help them succeed and remain relevant. This article discusses how brand companies can leverage their supplier network to answer the needs of the consumer, innovate rapidly, and achieve their speed to market goals.

RESOURCE ALLOCATION

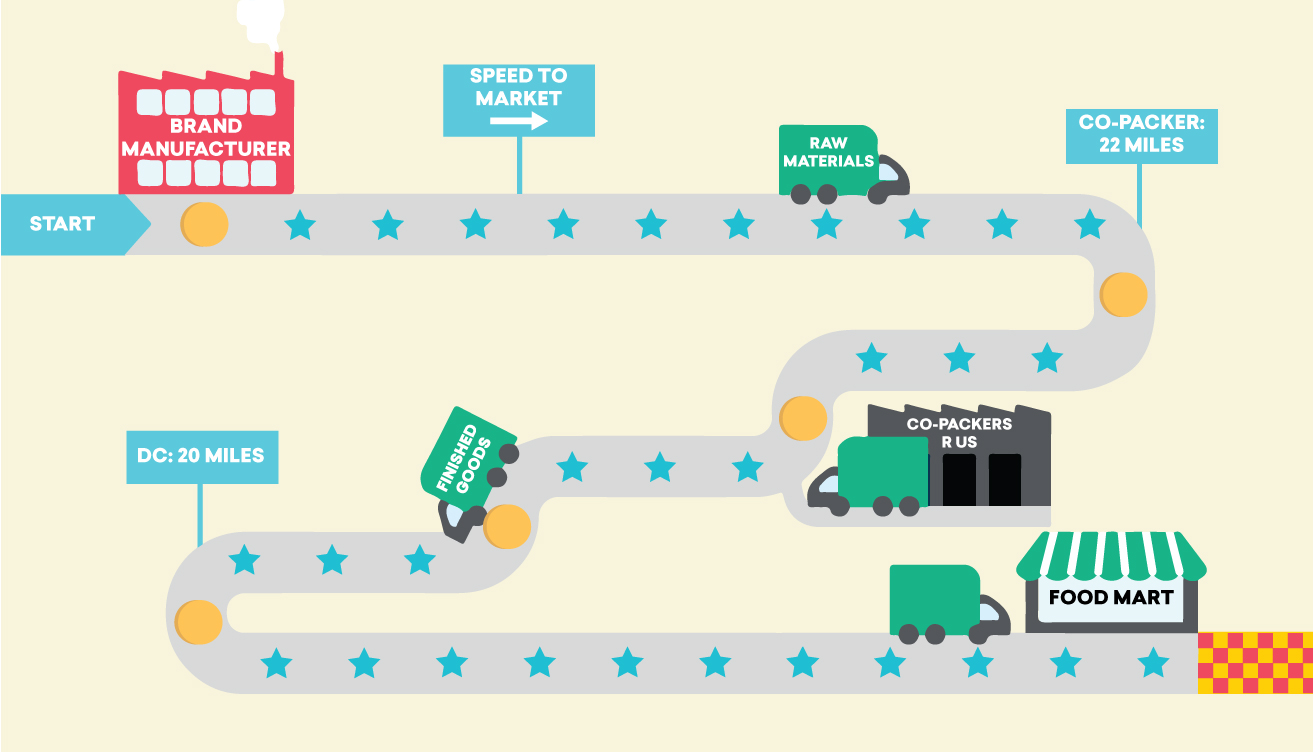

The first step to establishing a Late State Customization model is evaluating external resources. If you are currently using a co-packer, investigate their capabilities, facilities, and processes to determine whether they’re set up for maximum flexibility. It is critical to find a co-packer or co-manufacturer that can support quick changeovers, adaptable scheduling, flexible machinery, and warehouse space. A co-packer with short frozen zone windows can adapt quickly to changing demand, allowing companies to focus on R&D, market trends, and manufacturing their product. Additionally, finding a co-packer that can ship direct to retail is a major cost-savings. According to the 2017 Grocery Manufacturers Association Supply Chain Benchmarking Study, CPG companies bear 60% of the shipping cost burden. By running a late stage model, brand companies and co-packers can find a suitable plan for short-term storing of smaller production quantities at the co-packer’s site, eliminating the dual shipment of product from co-packer to distribution center to retailer.

OPTIMIZE FOR FLEXIBILITY

Once external resources have been identified for production flexibility, it’s time to look internally and structure the supply chain to support a late stage model. Ideally, a company will build an ecosystem of partners all working toward the same goal: to satisfy shortened lead times, allow for customization, and launch products successfully. Because of shortened timelines, and the need to launch and learn, brand companies are reducing order quantities to minimize risk and see how the market reacts. Instead of the age old model where companies produce massive quantities of the same SKU, now brands need to produce smaller amounts of new products very quickly. This model is not efficient unless a late stage supply chain has been established with strategic partners. Another key factor is logistics. With increasing transportation costs, manufacturers are looking for supply chain partners that are located in strategic locations to minimize time to market and movement of goods.

CHANGE TO WIN

With an ecosystem in place, it’s vital to lean on strategic partners. Without adopting this change mindset, it will be difficult to compete against other agile manufacturing models.

To mitigate downtime and increase speed to market, manufacturers would prefer to focus on what they do best: manufacturing. With requests from retailers and sales teams for various pack types and customization, it's difficult to gain efficiencies if multiple changeovers are required or there's frequent downtime. Margins will dilute and timelines will be pushed out. However, if the ecosystem is working, manufacturers can be more agile by deploying product in bulk and leaning on external supply chain partners to convert product to a finished good - satisfying both speed and custom pack requirements. Keeping in touch with the retailer will help brands understand and perhaps predict market trends for upcoming projects. This allows for manufacturing companies to satisfy unpredictable sales requirements. When an agile supply chain has been built, and the IT communication structure is in place, manufacturers can focus on manufacturing and work with strategic partners on building an adaptable project pipeline, where the main focus is responding to product trends, innovation, and manufacturing product, while strategic external partners are focusing on customization and shorter run times.

There are many elements to consider in moving toward a late stage customization model. Companies that spend the time to analyze their supply chain, set up an ecosystem to flow naturally in a late stage model, and lean on their key partners will be able to confidently implement a new business model: one that focuses on innovation and forward thinking.